Introduction

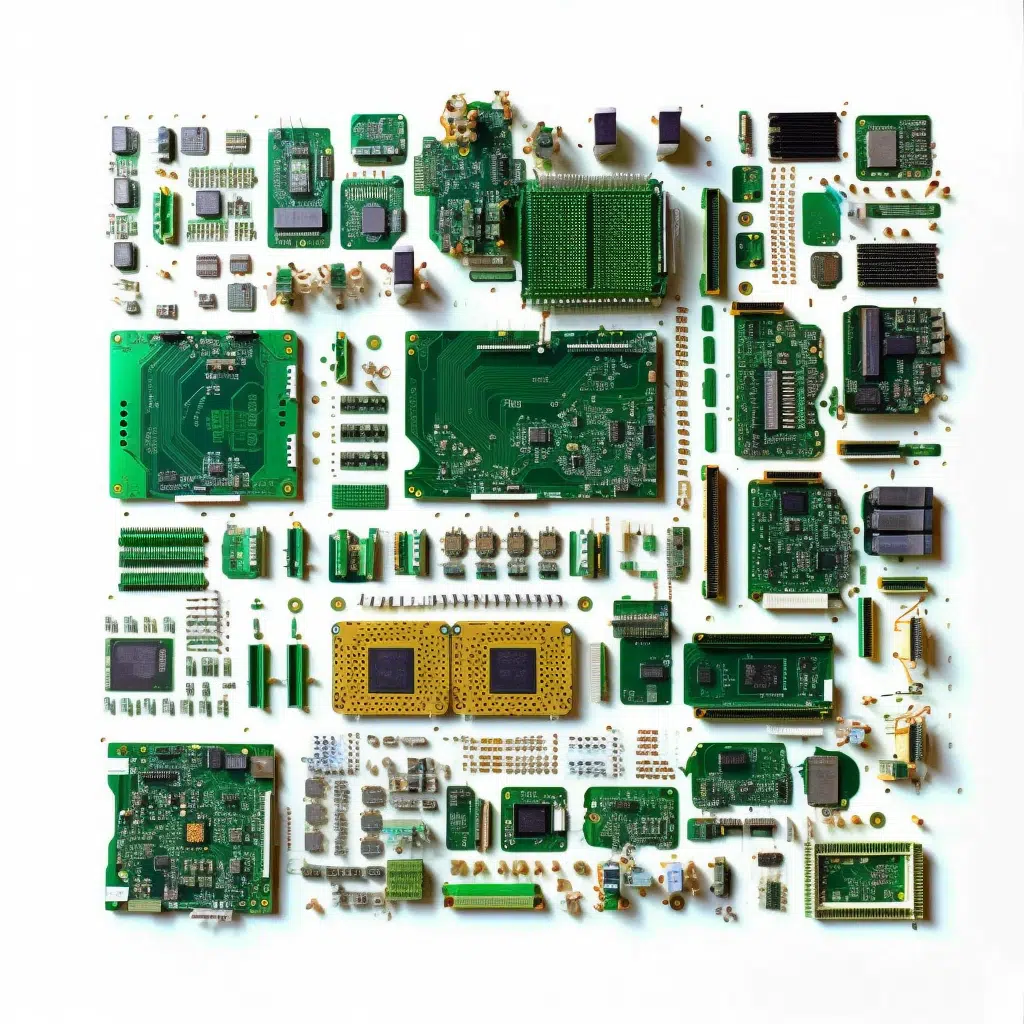

Printed Circuit Boards (PCBs) are the backbone of almost every electronic device we use today. From our smartphones and laptops to our televisions and even our kitchen appliances, PCBs are integral to their operation. They provide the necessary mechanical support and electrical connections for the components within these devices.

However, like any other component, PCBs are not immune to issues and failures. Over time and with extended use, various problems can arise that affect the functionality of the PCB, and by extension, the device it’s housed in. These issues can range from physical damage and component failure to design flaws and power issues.

Understanding these common PCB problems is the first step towards effective troubleshooting and repair. In the following sections, we’ll delve deeper into the world of PCBs, explore the most common issues they face, and discuss the best practices for their repair. Whether you’re a procurement manager, an electronics enthusiast, or someone simply interested in learning more about the inner workings of your everyday devices, this comprehensive guide aims to equip you with the knowledge you need.

Understanding PCBs and Their Importance in Electronics

Printed Circuit Boards (PCBs) are essentially the brains of our electronic devices. They are designed to electrically connect and mechanically support various components using conductive tracks, pads, and other features etched from copper sheets and laminated onto a non-conductive substrate.

PCBs are found in almost all electronic devices, making them a critical component in the electronics industry. They provide the foundation for the assembly of transistors, resistors, and integrated circuits. In essence, they are the platforms for electronic component interconnection, which is why their design and functionality are crucial for the overall performance of the device.

A Printed Circuit Board (PCB) is the backbone of all major electronic devices. It’s a board that connects and supports all the components of a device. You can learn more about PCBs here.

Common Issues that Necessitate PCB Repair

Despite their robust design and critical role, PCBs can encounter a variety of issues over time. These issues can be due to various factors, including physical damage, component failure, poor design, and power issues.

Physical damage can occur due to mishandling or harsh environmental conditions, while component failure can be due to aging or manufacturing defects. Poor design can lead to issues like short circuits, while power issues can result from voltage spikes or component failures.

Understanding these common issues is crucial for effective PCB repair. In the following sections, we will delve deeper into these problems and discuss the best practices for PCB repair.

Understanding PCBs and Common Issues

What is a PCB?

A Printed Circuit Board (PCB) is a thin board made of fiberglass, composite epoxy, or other laminate material. Conductive pathways are etched or printed onto this board in the form of tracks. These tracks connect different components on the PCB, such as transistors, resistors, and integrated circuits.

PCBs are the foundation of modern electronic equipment. They are used in everything from simple electronic devices like digital watches and calculators, to sophisticated computer systems and medical equipment. They come in various types, including single-sided, double-sided, and multi-layer boards.

Why do PCBs Fail?

Despite their critical role in electronics, PCBs can encounter a variety of issues that can lead to failure. Here are some common reasons why PCBs fail:

- Physical Damage: This is often the most visible cause of PCB failure. It can occur due to mishandling, dropping the device, or exposure to harsh environmental conditions. Physical damage can cause cracks or breaks in the PCB, damaging the conductive pathways and causing the PCB to fail.

- Component Failure: Components on the PCB can fail due to various reasons, including manufacturing defects, aging, or overheating. When a component fails, it can disrupt the electrical flow in the circuit, causing the PCB to fail.

- Poor Design: If a PCB is not properly designed, it can lead to issues such as short circuits or overheating. For example, if the components are too close together, it can cause overheating, which can lead to component failure and PCB failure.

- Power Issues: Power issues such as voltage spikes or power surges can cause damage to the PCB and its components. This can lead to immediate failure of the PCB or gradual degradation over time.

Understanding these common issues is the first step towards effective troubleshooting and repair. In the next section, we will discuss the most common PCB repairs and how they can be addressed.

The 5 Most Common PCB Repairs

PCB issues can range from minor to severe, and understanding the most common problems can help in effectively addressing them. Here are the five most common PCB repairs:

1.Repairing Physical Damage

Physical damage is one of the most common issues that PCBs face. This can include cracks or breaks in the board, damaged components, or even damage to the solder joints or traces. Physical damage can occur due to mishandling, dropping the device, or exposure to harsh environmental conditions.

- How to Diagnose and Repair: Diagnosing physical damage often involves a visual inspection of the PCB. Look for visible signs of damage like cracks, breaks, or damaged components. Repairing physical damage often involves replacing the damaged components and repairing the board using techniques such as soldering or reballing. It’s important to note that repairing physical damage should be done by a professional to avoid further damage to the board.

2.Addressing Component Failure

Components on the PCB can fail due to various reasons, including manufacturing defects, aging, or overheating. When a component fails, it can disrupt the electrical flow in the circuit, causing the PCB to fail. This can result in the device not working at all, or working intermittently.

- How to Diagnose and Repair: Diagnosing component failure involves testing the components on the PCB using tools like a multimeter. If a component is not functioning as expected, it may need to be replaced. Replacing a component requires precision and expertise to ensure that the new component is installed correctly and the PCB functions as intended.

3.Fixing Trace Damage

Traces are the thin lines of conductive material (usually copper) that connect the components on the PCB. Damage to these traces can disrupt the electrical connections, leading to PCB failure. This can result in a complete loss of functionality, or certain features of the device not working.

- How to Diagnose and Repair: Diagnosing trace damage involves a visual inspection of the PCB and testing the continuity of the traces using a multimeter. If a trace is damaged, it can be repaired by applying a new layer of conductive material, a process known as “retracing”.

4.Correcting Poor Design

Sometimes, PCB issues can be traced back to poor design. This can include components being placed too close together, leading to overheating, or improper routing of traces, leading to short circuits. Poor design can lead to a range of issues, from intermittent problems to complete device failure.

- How to Diagnose and Repair: Diagnosing poor design involves a thorough review of the PCB layout. If the design is found to be the cause of the issue, the PCB may need to be redesigned and replaced.

5.Resolving Power Issues

Power issues such as voltage spikes or power surges can cause damage to the PCB and its components. This can result in the device not turning on, or turning off unexpectedly.

- How to Diagnose and Repair: Diagnosing power issues involves testing the power supply and the components on the PCB. If a power issue is identified, the source of the issue needs to be addressed. This could involve replacing a faulty power supply or repairing or replacing any components damaged by the power issue.

Physical damage to a PCB can occur in several ways, such as impact, exposure to high temperatures, or corrosion. You can learn more about physical damage to PCBs and how it’s repaired here.

What Materials are Necessary for PCB Repairs?

Repairing a PCB requires various tools and materials. This can include a soldering iron for removing and replacing components, a multimeter for testing electrical connections, and conductive material for repairing traces. In some cases, specialized equipment like a rework station or a hot air gun may be needed. It’s also important to have replacement components available, as many PCB issues involve faulty components.

The Importance of Professional PCB Repair

While some minor PCB issues can be addressed with a basic understanding of electronics and the right tools, many PCB repairs are complex and require professional expertise. This is where the importance of professional PCB repair comes into play.

Why You Shouldn’t DIY PCB Repair

PCB repair and remanufacturing is a complex process that involves several steps. First, the faulty PCB is diagnosed to identify the issue. This can involve visual inspection, electrical testing, or even using specialized diagnostic equipment. Once the issue is identified, the faulty components are removed and replaced, and any damaged traces are repaired. The repaired PCB is then tested to ensure it functions correctly. In the case of remanufacturing, the PCB is repaired to the point where it meets the original manufacturer’s specifications.

Attempting to repair a PCB without the necessary skills and equipment can lead to further damage and potentially irreparable failure. Moreover, some components on a PCB are sensitive to static electricity and can be damaged by improper handling. Professional PCB repair services use anti-static measures to protect these components during the repair process.

The Role of Professional Repair Services

Professional PCB repair services have the expertise, tools, and materials necessary to effectively diagnose and repair a wide range of PCB issues. They can handle everything from physical damage and component failure to trace damage, poor design, and power issues.

In addition to repairing the immediate issue, professional repair services can also identify and address underlying issues that might lead to future failures. For example, if a PCB failure was caused by a design flaw, a professional repair service can redesign the PCB to prevent the issue from recurring.

Furthermore, professional repair services can remanufacture PCBs, which involves repairing a PCB to the point where it meets the original manufacturer’s specifications. This process can extend the life of your electronic devices and save you the cost of replacing the entire device.

In the next section, we will discuss how to choose the right PCB repair service and why Rowsum could be the perfect fit for your PCB repair needs.

Choosing the Right PCB Repair Service

When it comes to PCB repair, choosing the right service is crucial. Here are some factors to consider:

Experience and Expertise

Look for a service that has extensive experience and expertise in PCB repair. They should be able to handle a wide range of issues, from physical damage and component failure to trace damage and design flaws.

Rowsum, with its years of experience in the industry, has the expertise to handle all these issues and more. You can read about some of our success stories here.

Quality of Service

Quality should be a top priority when choosing a PCB repair service. The service should use high-quality components for replacements and adhere to industry standards for repair and remanufacturing.

At Rowsum, we prioritize quality above all else. We use high-quality components and follow strict quality control processes to ensure that our repairs meet or exceed the original manufacturer’s specifications. Learn more about our commitment to quality here.

Customer Service

Excellent customer service is another important factor to consider. The repair service should be responsive to your needs, provide clear communication, and offer reliable technical support.

Turnaround Time

If you’re relying on your electronic devices for your business or personal use, you can’t afford to be without them for long. Choose a repair service that offers quick turnaround times.

Cost-Effectiveness

Finally, consider the cost-effectiveness of the repair service. The service should offer competitive pricing without compromising on quality.

Why Choose Rowsum for Your PCB Repair Needs?

Rowsum ticks all the boxes when it comes to these factors. With our years of experience in the industry, we have the expertise to handle a wide range of PCB issues. We prioritize quality above all else, using high-quality components and following strict quality control processes. Our exceptional customer service, quick turnaround times, and competitive pricing make us a cost-effective choice for our clients. With Rowsum, you can rest assured that your PCBs are in good hands.

Conclusion

PCB issues can range from minor to severe, but understanding the most common problems and how to address them can go a long way in maintaining the longevity and performance of your electronic devices. While some minor issues can be addressed with a basic understanding of electronics and the right tools, many PCB repairs are complex and require professional expertise. That’s where Rowsum comes in. With our extensive experience, commitment to quality, exceptional customer service, quick turnaround times, and competitive pricing, we are a top choice for professional PCB repair and remanufacturing services.

Frequently Asked Questions

The most common PCB issues include physical damage, component failure, trace damage, poor design, and power issues.

- What are the most common PCB issues?

While some minor PCB issues can be addressed with a basic understanding of electronics and the right tools, many PCB repairs are complex and require professional expertise. Attempting to repair a PCB without the necessary skills and equipment can lead to further damage.

- Can I repair a PCB myself?

A professional PCB repair service offers the expertise, tools, and materials necessary to effectively diagnose and repair a wide range of PCB issues. They can handle everything from physical damage and component failure to trace damage, poor design, and power issues.

- What does a professional PCB repair service offer?

Rowsum offers extensive experience, a commitment to quality, exceptional customer service, quick turnaround times, and competitive pricing. We prioritize our clients’ needs and strive to provide the best possible service.

- Why should I choose Rowsum for my PCB repair needs?

You can learn more about Rowsum and our services by visiting our website at www.rowsum.com.

- Where can I learn more about Rowsum and its services?