Introduction

Have you ever wondered how the world of PCB engineering is evolving? Or perhaps, you’ve pondered over the role artificial intelligence (AI) plays in your day-to-day tasks as a PCB engineer? Well, you’re not alone. These are questions that many in our industry are asking.

Imagine this: You’re sitting at your desk, a cup of coffee in hand, staring at a complex PCB design on your computer screen. It’s a challenging project, and you’re trying to figure out how to optimize the design for manufacturing. Suddenly, your AI-powered design tool suggests a more efficient layout that reduces the number of layers and improves the overall performance of the board. You’re amazed. You think, “Is this the future of PCB engineering?”

The truth is, this isn’t just a glimpse into the future. It’s happening right now. AI is already making waves in the PCB engineering world, and it’s changing the game in ways we could only dream of a few years ago.

But what does this mean for you, the PCB engineer? Is AI here to replace you? Or is it here to make your job easier and more exciting?

In this article, we’ll explore these questions and more. We’ll delve into the impact of AI on PCB design and manufacturing, and how it’s reshaping the role of the PCB engineer. So, buckle up and join us on this exciting journey into the future of PCB engineering!

The Evolution of PCB Engineering

Let’s take a step back and look at where we’ve come from. The world of PCB engineering has seen a remarkable evolution over the years. Remember the days when PCB designs were drawn by hand? Those were the days of painstaking precision, endless erasing, and redrawing. It was a laborious process, but it was all we had.

Traditional PCB Design and Manufacturing

In the traditional approach to PCB design and manufacturing, engineers spent countless hours manually creating and optimizing designs. The process was time-consuming and prone to human error. Manufacturing, too, was a complex process. It involved numerous steps, from etching and drilling to soldering and testing. Each step required meticulous attention to detail and a high level of skill.

The Advent of AI in PCB Engineering

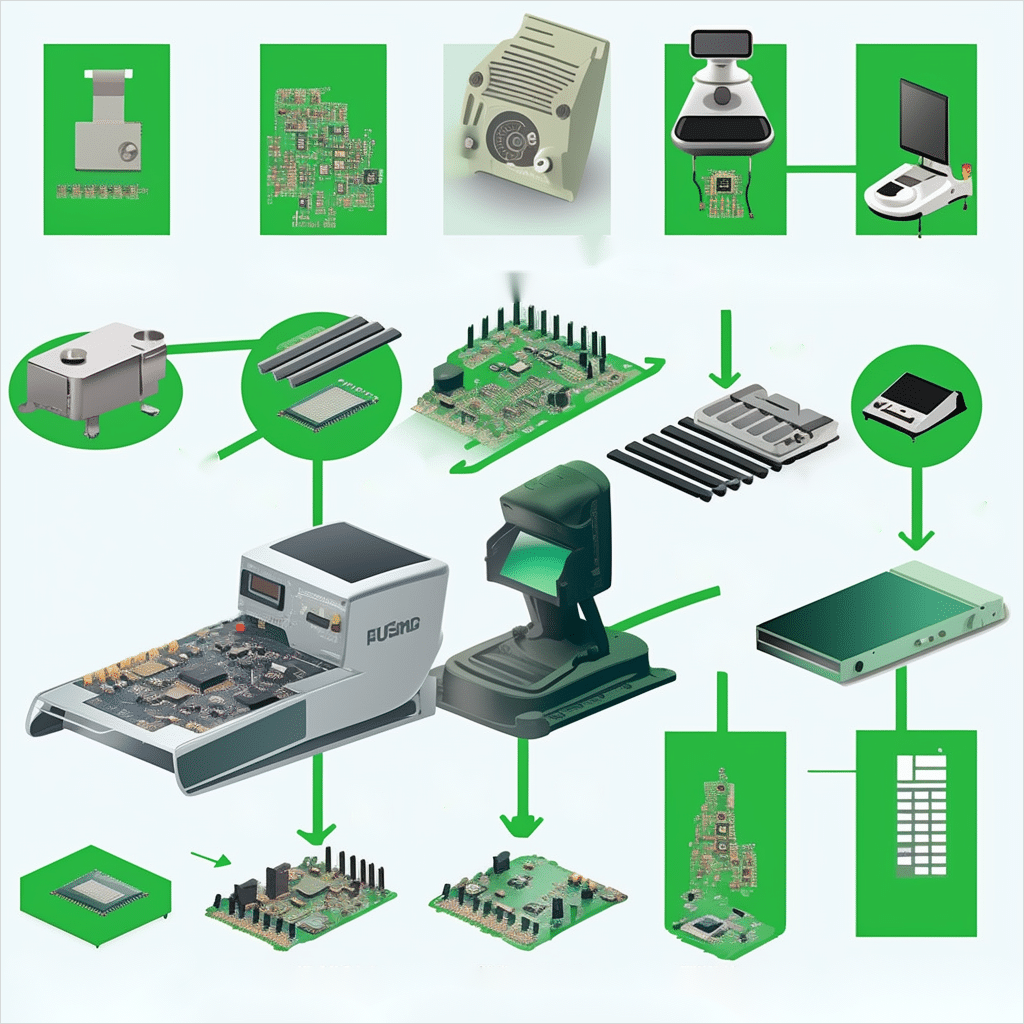

Fast forward to today, and the landscape of PCB engineering has changed dramatically. The advent of AI has ushered in a new era of efficiency and precision. AI-powered tools are now capable of automating many of the tasks that once required hours of manual labor. These tools can analyze complex designs, suggest optimizations, and even predict potential issues before they occur.

But the impact of AI goes beyond just design. It’s also transforming the way we manufacture PCBs. AI-driven automated production lines are now a reality, enabling faster and more efficient manufacturing processes. Quality control, too, has seen significant improvements with the help of AI.

So, what does this mean for you, the PCB engineer? Is this evolution a threat or an opportunity? Let’s dive deeper into the role of AI in PCB design and manufacturing to find out.

Stay tuned as we explore how AI is not only changing the way we work but also opening up new possibilities for innovation and creativity in the world of PCB engineering.

AI’s Role in Assisting PCB Engineers

AI is not here to replace engineers but to assist them, and it’s doing so in some truly remarkable ways. Let’s delve deeper into how AI is transforming the role of PCB engineers.

AI-Driven Design Tools for PCB Engineers

One of the most significant ways AI is assisting PCB engineers is through AI-driven design tools. These tools leverage machine learning algorithms to analyze complex PCB designs and suggest optimizations. They can identify potential issues in the design phase, reducing the need for costly and time-consuming revisions later on.

For example, tools like Altium Designer and Cadence Allegro leverage AI to help in routing optimization, component placement, and thermal management. They can analyze a design and suggest the most efficient routing paths or the optimal placement of components to minimize heat generation. This not only improves the performance of the PCB but also reduces the time engineers need to spend on these tasks.

AI Enhancing Efficiency and Accuracy in PCB Design

AI’s ability to analyze vast amounts of data quickly and accurately is a game-changer for PCB design. It can identify patterns and trends that would be impossible for a human to spot, leading to more efficient and accurate designs.

For instance, AI can predict the performance of a PCB design under various conditions, such as different temperatures or voltages. This allows engineers to make informed decisions about their designs and avoid potential issues down the line.

AI Fostering Creativity and Innovation in PCB Design

While AI is great at analyzing data and making predictions, it’s also proving to be a valuable tool for fostering creativity and innovation. AI can generate new design ideas based on previous designs, pushing the boundaries of what’s possible in PCB design.

For example, generative design, an AI technique that generates a wide range of design options based on a set of predefined constraints, is starting to make its way into PCB design. This allows engineers to explore a wider range of design possibilities and come up with innovative solutions to complex design challenges.

In conclusion, AI is proving to be a valuable ally for PCB engineers. It’s not here to replace engineers but to assist them, making their jobs easier and more exciting. As we continue to explore the potential of AI in PCB engineering, the future looks bright.

AI in PCB Manufacturing: A Boon for Engineers

In the realm of PCB manufacturing, AI is not just a buzzword; it’s a game-changer. It’s transforming the way PCB engineers work, making their jobs easier, more efficient, and more effective. Here’s how:

AI-Powered Design Tools

AI-powered design tools are revolutionizing the PCB design process. Tools like Altium Designer and OrCAD are incorporating AI capabilities to assist engineers in creating more efficient and reliable designs. These tools can predict potential design issues, suggest optimal component placements, and even automate some of the more tedious aspects of PCB design. This not only saves time but also improves the quality of the final product.

Quality Control and Defect Detection

Quality control is a critical aspect of PCB manufacturing. Traditionally, this process involved manual inspection and testing, which can be time-consuming and prone to errors. With AI, this process can be automated and made more accurate. AI algorithms can analyze images of PCBs to detect defects such as missing components, incorrect component placements, and soldering issues. This allows for quicker and more accurate defect detection, leading to improved product quality.

Predictive Maintenance

AI can also be used to predict potential equipment failures in the PCB manufacturing process. By analyzing data from sensors on the manufacturing equipment, AI algorithms can identify patterns and predict when a machine is likely to fail. This allows for preventative maintenance, reducing downtime and increasing overall manufacturing efficiency.

Supply Chain Optimization

AI can also help optimize the supply chain in PCB manufacturing. By analyzing historical data, AI can predict future demand for certain components, helping manufacturers manage their inventory more effectively. This can reduce costs and ensure that production is not delayed due to lack of components.

Training and Support

Finally, AI can also be used to provide training and support to PCB engineers. AI-powered chatbots can answer common questions, provide troubleshooting support, and even guide engineers through complex design processes. This can help engineers improve their skills and solve problems more quickly.

In conclusion, AI is proving to be a valuable tool in PCB manufacturing, assisting engineers in various aspects of their work. As AI technology continues to advance, we can expect it to play an even more significant role in the future of PCB engineering.

Get Access Now: www.rowsum.com

Will AI Replace PCB Engineers?

The question looms large in the minds of many in the industry: Will AI replace PCB engineers? It’s a question that echoes the fears and uncertainties that accompanied the dawn of the Industrial Revolution. But just as the steam engine didn’t replace the engineer, but rather changed the nature of their work, AI is set to do the same.

AI as a Tool, Not a Replacement

AI, in essence, is a tool. A powerful, transformative tool, but a tool nonetheless. It’s like a high-powered microscope, allowing us to see patterns and make predictions that would be impossible with the naked eye. But while a microscope can reveal the intricate details of a cell, it cannot understand the beauty of a sunset or the melody of a symphony. Similarly, AI can analyze data and automate tasks, but it lacks the creativity, critical thinking, and problem-solving skills that are the hallmark of a human engineer.

The Human Touch in PCB Engineering

PCB engineering is as much an art as it is a science. It involves understanding the needs of the end-user, coming up with innovative solutions to complex design challenges, and making critical decisions that impact the performance and functionality of the PCB. These are tasks that require not just technical skills, but also creativity, intuition, and empathy. They require the human touch.

Imagine a symphony orchestra. AI might be able to play each instrument perfectly, but it takes a human conductor to bring them all together, to understand the emotion in the music, and to create a performance that moves the audience. Similarly, while AI can automate certain tasks in PCB engineering, it takes a human engineer to bring it all together and create a PCB that truly meets the needs of the user.

The Future of PCB Engineering: A Symphony of Humans and AI

The future of PCB engineering is not a battle between humans and AI, but a symphony. A symphony where AI and human engineers work together, each playing to their strengths. AI can take care of the routine and repetitive tasks, freeing up human engineers to focus on the creative and complex aspects of PCB design and manufacturing. This collaboration could lead to more innovative and high-quality PCBs, benefiting both the industry and the end-users.

In conclusion, while AI is set to transform the world of PCB engineering, it’s not here to replace human engineers. Instead, it’s here to assist them, to amplify their skills, and to make their jobs more exciting. Just as the steam engine didn’t replace the engineer but changed the nature of their work, AI is set to do the same. The future of PCB engineering is not a choice between humans and AI, but a collaboration between the two.

The Future of AI and PCB Engineering

As we gaze into the future, it’s clear that AI will continue to play a significant role in PCB engineering. But what exactly will that future look like? Let’s delve into some specifics.

The Emergence of Advanced AI-Driven Tools

In the future, we can expect to see a surge in the development and use of advanced AI-driven tools in PCB design and manufacturing. These tools will not only be more sophisticated but also capable of handling more complex tasks and making more accurate predictions. For instance, AI-powered software like Altium Designer and Cadence Allegro are already making waves in the industry, and we can expect more such tools to emerge. These tools will make the design and manufacturing process even more efficient and reliable, freeing up engineers to focus on the more creative and challenging aspects of their work.

AI and Human Intelligence: A Powerful Collaboration

The future of PCB engineering will not be a choice between humans and AI, but a collaboration between the two. AI will handle the data analysis and automation, while humans will provide the creativity and critical thinking. This synergy will lead to more innovative and high-quality PCBs, benefiting both the industry and the end-users. For instance, AI can be used to automate the routing process, while engineers can focus on optimizing the design for better performance.

The Need for Continuous Learning and Adaptation

As AI continues to evolve, PCB engineers will need to keep up. This means continuous learning and adaptation will be key. Engineers will need to stay updated on the latest AI technologies and learn how to effectively use AI tools in their work. This will not only make them more effective in their jobs but also open up new opportunities for career growth and advancement. For instance, engineers can take online courses or attend workshops to learn about the latest AI tools and techniques.

The Emergence of New Opportunities and Challenges

Finally, the integration of AI in PCB engineering will bring new opportunities and challenges. On one hand, it will open up new possibilities for innovation and creativity. On the other hand, it will raise new questions about ethics, privacy, and security. As we navigate this new landscape, it will be important to have open and honest discussions about these issues and to develop strategies to address them.

In conclusion, the future of AI and PCB engineering is bright. It’s a future of collaboration, innovation, and continuous learning. And as we move forward, one thing is clear: the role of the PCB engineer is not being replaced by AI; it’s being redefined.

Get Access Now: www.rowsum.com

Conclusion

The advent of AI in PCB engineering is not a threat but an opportunity. It’s an opportunity for engineers to leverage powerful tools to enhance their work, to focus on the creative and complex aspects of PCB design and manufacturing, and to redefine their roles in an exciting new landscape.

AI is here to assist, not replace. It’s here to make the jobs of PCB engineers easier, more efficient, and more exciting. It’s here to open up new possibilities for innovation and creativity. And as we move forward, it’s clear that the future of PCB engineering is not a choice between humans and AI, but a collaboration between the two.

So, as a PCB engineer, embrace this change. Keep learning, keep adapting, and be ready to seize the opportunities that this AI-driven future holds. The future is bright, and it’s yours to shape.

FAQs

- Will AI replace PCB engineers?

No, AI is not here to replace PCB engineers. Instead, it’s here to assist them, making their jobs easier and more efficient. The future of PCB engineering is a collaboration between humans and AI.

- What are some AI-driven tools for PCB design and manufacturing?

There are several AI-driven tools available for PCB design and manufacturing, such as Altium Designer and Cadence Allegro. These tools can automate certain tasks and make the design and manufacturing process more efficient.

- How can PCB engineers prepare for an AI-driven future?

PCB engineers can prepare for an AI-driven future by continuously learning and adapting. This includes staying updated on the latest AI technologies and learning how to effectively use AI tools in their work.

- What are some opportunities and challenges that AI brings to PCB engineering?

AI brings several opportunities to PCB engineering, including increased efficiency, the ability to handle complex tasks, and new possibilities for innovation. However, it also brings challenges, such as the need for continuous learning and adaptation, and questions about ethics, privacy, and security.

- How is AI changing the role of the PCB engineer?

AI is changing the role of the PCB engineer by automating routine and repetitive tasks, freeing up engineers to focus on more creative and complex aspects of PCB design and manufacturing. It’s also providing powerful tools that can enhance the work of engineers and open up new possibilities for innovation.