Introduction

When the Sphere first caught my eye, I’ll admit, I wasn’t moved. It seemed like just another flashy addition to Las Vegas—a place to display emojis and ads, another landmark in a city of spectacles. But then, I stumbled upon a blogger’s video tour of its interior, and my perspective shifted dramatically. What I saw was not just a display; it was an all-encompassing visual feast, a testament to the pinnacle of entertainment technology.

In my line of work within the manufacturing sector, the idea of contributing to such an architectural feat is incredibly fulfilling. This structure isn’t just another job—it’s a transformative project that will undoubtedly shift the paradigm of audience immersion. That’s where my fascination with the Sphere truly began.

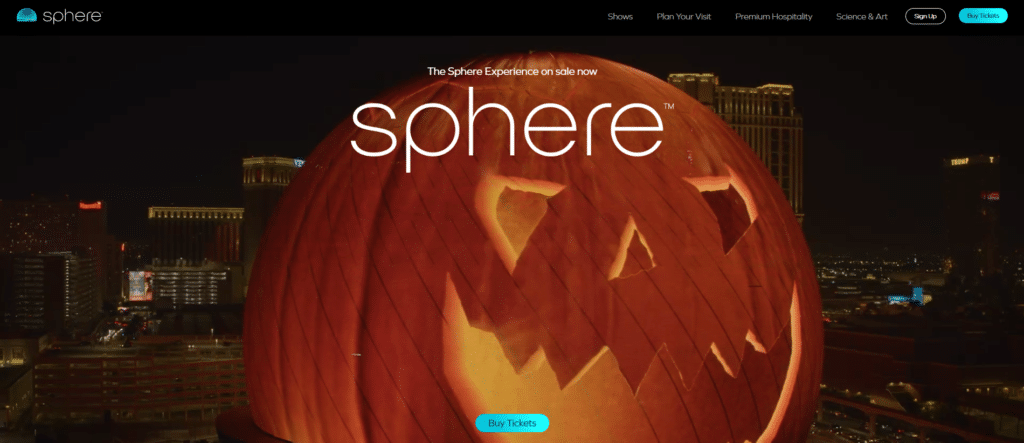

*Image courtesy of MSG Sphere official website.*

Unveiling the MSG Sphere: An Overview

The MSG Sphere at The Venetian is not merely an addition to the Las Vegas Strip; it is a leap into the future of entertainment architecture. This section draws upon insights from Popular Mechanics and Vital Vegas to unveil the marvel that is the MSG Sphere.

Architectural Grandeur Meets Technological Prowess

At 366 feet tall and 516 feet wide, the MSG Sphere stands as a monument to human ingenuity in modern construction. The screen resolution inside the Sphere is unprecedented, boasting 19,000 by 13,500 pixels—100 times clearer than the best HD TVs available, covering an area larger than three football fields. This feat of visual engineering is a testament to the collaboration between visionary architects and leading manufacturers who are pushing the boundaries of what’s possible in large-scale entertainment venues.(Source: Popular Mechanics)

A Canvas of Light: The Exterior’s Programmable Lighting

The Sphere’s exterior is a technological masterpiece, with approximately 600,000 square feet of programmable LED lighting. This feature, crafted by SACO Technologies, transforms the building into a living mural, visible for miles and setting a new standard for interactive architecture. The lighting system creates a platform not just for advertising, but for artistry on a grand scale.(Source: Vital Vegas)

Revolutionizing Acoustics: The Beamforming Sound System

Inside, the Sphere will be alive with the sound of innovation. The “beamforming” sound system, with its 157,000 ultra-directional speakers, is designed to direct sound to specific locations within the venue with unparalleled precision. This acoustic marvel will allow every seat to become a sweet spot, enveloping each member of the audience in a cocoon of sound.

The Weight of Wonder: The Dome’s Structural Feats

The dome itself is a marvel of engineering, weighing 13,000 tons and supported by six million pounds of steel. The manufacturers and engineers behind this colossal structure have achieved a balance of form and function, creating a space that is as safe and sturdy as it is aesthetically pleasing.

Bridging the Experience: The Pedestrian Bridge

The 1,000-foot pedestrian bridge connecting the Sphere to the Sands Expo is more than a pathway; it’s a journey to an extraordinary experience. The bridge’s construction is a collaboration between civil engineers and manufacturers who specialize in creating structures that are both functional and emblematic of the innovative spirit of the Sphere.

The Sphere’s Role in Las Vegas’ Entertainment Tapestry

The MSG Sphere is set to become an iconic fixture in Las Vegas, a city known for its dazzling entertainment. Its construction is a collaborative effort involving multiple manufacturers, each contributing their expertise to create a venue that embodies the spirit of innovation and luxury that Las Vegas represents.

The Architectural Marvel Through a PCB & PCBA Lens

In the heart of Las Vegas, the MSG Sphere stands as a beacon of technological advancement, a testament to the seamless integration of audiovisual marvels. Behind the scenes, this integration is made possible by sophisticated PCBs and PCBAs that form the core of the Sphere’s immersive experience. As we delve into the components that make this possible, it’s essential to recognize how these innovations translate into tangible benefits for our clients.

Audio Signal Processing Capabilities

The Sphere’s auditory experience is a critical component of its allure. To achieve such high-quality audio output, PCBs are likely to integrate components such as:

- Digital Signal Processors (DSPs): DSP chips are crucial for high-speed audio signal processing, handling complex algorithms to simulate 3D sound effects. For instance, chips like the Texas Instruments TMS320 series could provide the necessary processing power.

- Audio Codecs: These chips convert analog audio signals to digital and vice versa, essential for maintaining audio fidelity. Chips from manufacturers like Cirrus Logic are often employed in high-end audio applications.

- Operational Amplifiers and Filters: High-performance op-amps and filters are used to modulate signals and suppress noise, ensuring clarity and quality of the audio signals.

Behind the Scenes of Luminosity

The Sphere’s lighting is as impressive as its sound, with the PCBs controlling it having to be equally up to the task. For such applications, Metal Core PCBs (MCPCBs) are the go-to choice due to their superior heat dissipation capabilities. This is crucial for maintaining the longevity and brightness of the extensive LED arrays that adorn the Sphere’s exterior. By using MCPCBs, we ensure that the LEDs operate at optimal temperatures, which is vital for keeping them bright and long-lasting. This approach not only enhances the visual spectacle but also contributes to energy efficiency and reduced maintenance needs.

Ensuring Long-Term Reliability

The longevity and reliability of PCBs are paramount, especially in a high-profile venue like the MSG Sphere. Key considerations include:

- Surface Treatment Processes: ENIG (Electroless Nickel Immersion Gold) is often chosen for its corrosion resistance and excellent conductivity, providing durable and reliable connections.

- Material Selection: Materials with high TG (Glass Transition Temperature) and CTI (Comparative Tracking Index) are preferred for their ability to withstand high temperatures and voltages. While FR-4 is a common choice, advanced applications might require materials like PTFE or ceramic substrates.

- Multilayer PCB Design: Complex circuit designs necessitate multilayer PCBs, which enhance signal integrity and mechanical stability.

*Image courtesy of MSG Sphere official website.*

Mastering PCB & PCBA Manufacturing: A Hypothetical Analysis for the MSG Sphere

The MSG Sphere, with its cutting-edge design, is a testament to the prowess of companies like SACO Technologies. While SACO Technologies is credited with the actual production, let’s hypothetically examine the kind of PCB & PCBA manufacturing challenges that a project of this scale might present and how a manufacturer like Rowsum could address them with expert solutions.

Theoretical Production Challenges

In a hypothetical scenario, manufacturing PCBs & PCBAs for an advanced project like the MSG Sphere could present several challenges:

- Intricate Audiovisual Integration: The seamless integration of audio and visual elements requires precision-engineered PCBs.

- High-Density Interconnects (HDI): The complexity of HDI PCBs, necessary for advanced control systems, poses significant manufacturing challenges.

- Thermal Management for LED Arrays: Managing the heat generated by extensive LED arrays is crucial to prevent system failures.

- Consistency in Mass Production: Ensuring each PCB & PCBA maintains consistent quality in mass production is a formidable task.

Hypothetical Engineering Solutions

Drawing from our extensive experience, here are the solutions that a manufacturer like Rowsum might implement:

- Precision Engineering Tools: Leveraging state-of-the-art engineering tools to design and verify complex PCB layouts.

- Material Science Expertise: Selecting advanced materials that cater to the specific thermal and structural demands of the project.

- Innovative Thermal Solutions: Employing innovative thermal management techniques to ensure longevity and reliability of the LED systems.

- Rigorous Quality Assurance: Implementing a comprehensive quality assurance protocol to maintain consistency across large-scale production runs.

Speculative Testing Protocols

While we can only speculate, it’s likely that a comprehensive testing protocol would be in place to ensure the reliability of such a project’s components:

- Extended Life Testing: Conducting long-term operational tests to predict and enhance the lifespan of the PCBs.

- Environmental Stress Tests: Subjecting PCBs to a variety of environmental stressors to ensure robust performance.

- Vibration and Shock Testing: Testing the PCBs’ ability to withstand the dynamic environment of a live entertainment venue.

- Comprehensive Electrical Tests: Ensuring all electrical components meet the stringent requirements necessary for a flawless audiovisual experience.

Conclusion: Pioneering PCB & PCBA Excellence in Next-Gen Entertainment

As we reflect on the technological spectacle that is the MSG Sphere, it becomes a benchmark for the kind of excellence we, at Rowsum, aspire to in every project we undertake. While we did not contribute to this particular marvel, it stands as a testament to the heights PCB and PCBA technology can reach and the transformative experiences they can create.

At Rowsum, our mission is to empower the future of entertainment with our high-quality PCB and PCBA solutions. We are committed to innovation, ensuring that our clients’ projects resonate with the same caliber of reliability and performance that the MSG Sphere exemplifies. Our dedication to pushing the boundaries of what’s possible positions us as a leading partner for businesses looking to make their mark in the entertainment industry.

As we move forward, the MSG Sphere inspires us to continue refining our processes, investing in cutting-edge technology, and upholding the highest standards of quality. We are poised to support the evolution of entertainment venues, contributing to the next generation of immersive experiences.

In closing, the MSG Sphere is not just a marvel of the present but a beacon for the future. At Rowsum, we are excited to bring our expertise to the table, ready to collaborate on projects that redefine the landscape of entertainment technology.

* The cover image used in [The MSG Sphere: A PCB & PCBA Manufacturing Perspective] is sourced from the MSG Sphere official website.*