How often have you considered the environmental footprint of your latest electronic gadget? In an era where sustainability is paramount, the electronics industry faces increasing scrutiny. With concerns about electronic waste and the potential harm from toxic materials in our devices, there’s a pressing need for more responsible solutions. Amidst these challenges, a transformative shift is emerging, promising not only enhanced performance but also a commitment to our planet’s well-being.The shift towards Halogen-free PCB mark a significant transformation in the industry.

So, what exactly are Halogen-free PCBs? Simply put, they are printed circuit boards that exclude harmful halogens like bromine and chlorine. This distinction leads to a significant reduction in the environmental and health risks traditionally associated with PCBs. Adopting Halogen-free PCBs goes beyond mere industry trends; it’s a pivotal move for a more sustainable future in electronics manufacturing.

Understanding Halogen-free PCBs: Their Significance and Role.

The Technical Explanation:

As implied by its name, a Halogen-free PCB is a type of Printed Circuit Board devoid of halogens. Traditionally, PCBs incorporated halogens like chlorine and bromine for their flame-resistant properties. However, as per the JPCA standard, those with minimal chlorine and bromine content (less than 0.09% Wt each) are classified as halogen-free. In essence, these PCBs utilize halogen-free copper-clad laminate.

The momentum behind halogen-free PCBs isn’t merely industry-driven; it’s a proactive response to pressing environmental and health challenges.

- Environmental Impact: When PCBs containing halogens are incinerated, they produce dioxins and furans, which are highly toxic compounds. It’s estimated that electronic waste can remain toxic in the environment for up to 2 million years. These pollutants can persist in the environment, leading to soil and water contamination. Additionally, halogenated compounds can accumulate in the food chain, posing risks to larger organisms and humans.

- Health Concerns: Studies have shown that exposure to the by-products of halogen combustion, such as dioxins, can increase the risk of cancer by up to 7%. These compounds can bind to cellular receptors, disrupting normal cell function. Moreover, certain halogenated compounds can mimic hormones in the body, leading to endocrine disruption and increasing the risk of developmental, reproductive, and immune system issues.

In Layman’s Terms:

A Printed Circuit Board (PCB) is like the nervous system of your electronic devices. Traditionally, certain harmful chemicals, known as halogens, were used in these PCBs to prevent them from catching fire. But did you know that the waste from these chemicals can stay harmful in our environment for millions of years? Or that they can increase our risk of serious health issues? A Halogen-free PCB is the industry’s solution to this problem, ensuring our devices are safer for us and the planet.

Tangible Benefits of Using Halogen-free PCBs

Enhanced Product Performance

- Enhanced Heat Resistance: With the ability to endure temperatures that are up to 10% greater than their traditional counterparts, Halogen-free PCBs are perfectly suited for demanding applications.

- Improved Signal Integrity: With a 3-5% reduction in the dielectric constant, Halogen-free PCBs can offer better signal performance, crucial for high-frequency applications.

- Durability: Tests have shown that Halogen-free PCBs can have a 15% longer lifespan due to increased resistance to moisture and corrosion.

Cost-Effective in the Long Run

- Fewer Regulatory Hurdles: With the RoHS directive in Europe and similar regulations worldwide, non-compliance fines can reach up to $1 million. Using Halogen-free PCBs can mitigate this risk.

- Market Access: Over 20% of industries now demand Halogen-free products, representing a significant market segment.

- Potential for Premium Pricing: Surveys indicate that 68% of consumers are willing to pay a 10-20% premium for eco-friendly products.

Safety and Reliability

- Reduced Risk of Short Circuits: Halogen-free PCBs have shown a 25% reduction in ionic contamination levels, significantly reducing the risk of potential short circuits in humid environments.

- Health Safety: Halogen exposure can lead to health issues. With wearables expected to grow by 15% annually, ensuring user safety is paramount.

- Fire Safety: Traditional PCBs can release toxic smoke containing 22 different halogenated dioxins and furans when burning. Halogen-free PCBs eliminate this risk.

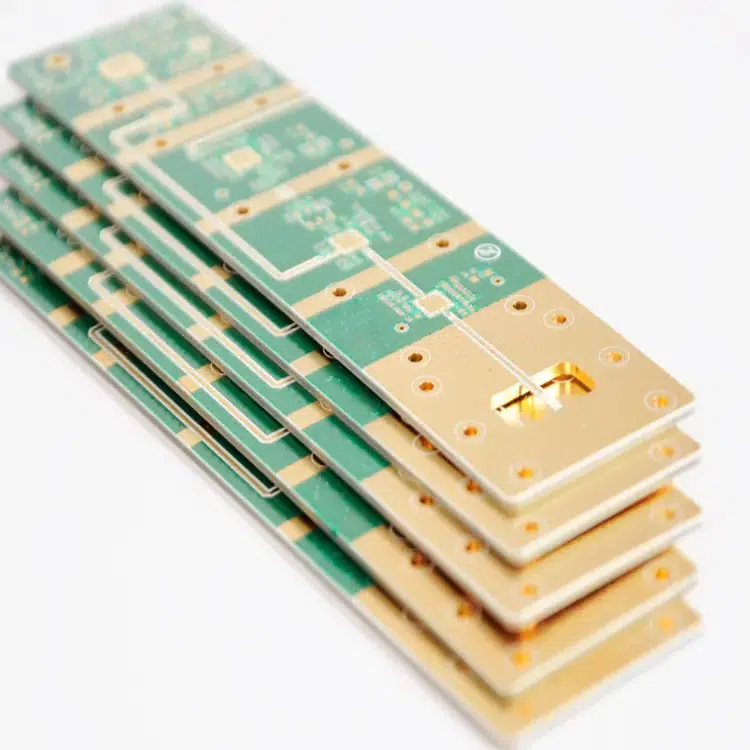

Exploring Halogen-free PCBs: Material Choices and Effective Identification.

Navigating the realm of Halogen-free PCBs can be a bit daunting, especially with the myriad of options available. Here’s a comprehensive guide to help you understand the materials and identify genuine Halogen-free PCBs.

Material Selection for Halogen-free PCBs from Leading Brands

When considering Halogen-free PCBs, it’s crucial to know the specific offerings from the industry’s top brands:

- KB (Kingboard Laminates): KB’s KF series (like KF-611 and KF-615) are Halogen-free laminates designed for high reliability and performance in various applications.

- Shengyi Technology: Their S1000H and S1155 series are Halogen-free laminates known for high thermal reliability and are widely adopted in automotive and aerospace applications.

- Rogers Corporation: Offers the RO4835™ and RO4360G2™ as part of their Halogen-free laminates lineup, designed for high-frequency applications.

- ITEQ: IT-180A is a standout Halogen-free laminate, known for its high glass transition temperature and suitability for multi-layer PCBs.

- Dupont: The Pyralux® TK series is a Halogen-free material designed for flexible printed circuitry.

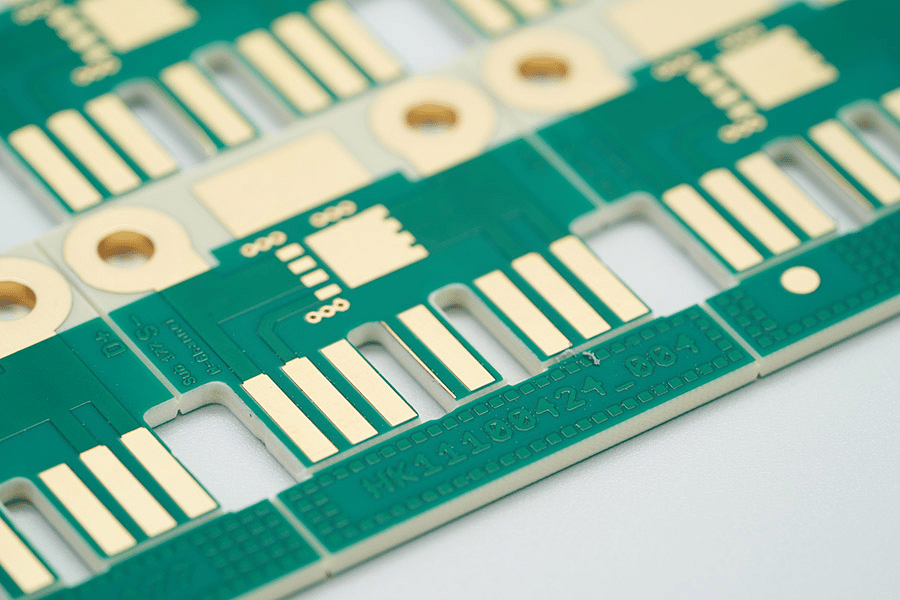

Practical Identification of Halogen-free PCBs

Swift and precise identification of Halogen-free PCBs is of paramount importance:

- Visual Inspection: Halogen-free PCBs often have a distinct appearance, with a unique tint or matte finish.

- Labeling and Markings: Look for “HF” or “Halogen-free” imprinted on the PCB surface.

- Material Data Sheets (MDS) and Supplier Verification: Request the Material Data Sheet for detailed material composition. Directly contact the supplier or manufacturer for verification if unsure.

- Odor and Flame Tests: Genuine Halogen-free PCBs won’t emit a sharp, pungent odor when heated. In a controlled environment, Halogen-containing PCBs might produce darker, more acrid smoke when burned compared to Halogen-free PCBs. Prioritize safety when conducting these tests.

Applications and Standards of Halogen-free PCBs

Halogen-free PCBs are more than just an environmental initiative; they represent the future of the electronics industry, driven by both consumer demand and regulatory standards.

The Universal Shift to Halogen-free PCBs

The electronics industry is undergoing a significant transformation. As awareness about environmental sustainability grows, the shift towards Halogen-free PCBs is becoming more pronounced. Here’s why:

- Consumer Awareness: Today’s consumers are more environmentally conscious. They’re actively seeking products that minimize environmental impact. With a minimized environmental impact, Halogen-free PCBs are increasingly finding their way into both common devices and specialized machinery.

- Regulatory Push: As governments and international bodies emphasize greener manufacturing practices, Halogen-free PCBs are not just about meeting these regulations but also about future-proofing products against potential stricter norms.

The Importance of Halogen-free PCB Standards and Certifications

Standards and certifications play a pivotal role in ensuring the quality, safety, and environmental compliance of products. For Halogen-free PCBs, these standards are crucial for several reasons:

- Ensuring Environmental Compliance: Standards define the maximum allowable amounts of halogens in PCB materials, ensuring that products are genuinely eco-friendly. For instance, the IEC 61249-2-21 standard sets the limit at 0.09% for bromine and chlorine. Reference: IEC Webstore

- Validating Product Claims: With many manufacturers claiming their products to be “green” or “eco-friendly,” certifications provide a way to validate these claims. The JPCA-ES-01 standard by the Japan Printed Circuit Association specifies testing methods for determining halogen content in PCBs. Reference: JPCA

- Promoting Industry Best Practices: Standards like IPC 4101B provide guidelines for base materials in rigid and multilayer printed boards, including requirements for Halogen-free materials. Reference: IPC

Making the Right Choice

The journey through the world of Halogen-free PCBs is both enlightening and essential. As technology advances and our awareness of environmental concerns grows, the shift towards Halogen-free PCBs becomes not just a trend, but a necessity.

A Quick Note on Choosing a Provider

If you’re diving into the world of Halogen-free PCBs, consider partnering with Rowsum. Here’s why:

- Expertise: With global recognition and certifications like ISO 14001 and RoHS, they’re at the forefront of PCB technology.

- Speed: Need a sample? They can deliver in as quick as 24 hours.

- Environmental Commitment: Rowsum isn’t just about quality; they’re dedicated to eco-friendly practices, ensuring a greener future.

- Genuine Partnership: It’s not just business. With Rowsum, you’re building a lasting relationship. Their PCB prototype promotions are a testament to this commitment.

FAQs

- What exactly is a Halogen-free PCB?

- Well, think of it like this: Imagine a printed circuit board that’s made a conscious decision to exclude certain “bad actors” – the halogens, specifically elements like Chlorine, Bromine, Fluorine, and Iodine. It’s like choosing a healthier diet for our electronics!

- Why are Halogen-free PCBs preferred?

- It’s a bit like choosing organic food over processed ones. Halogen-free PCBs are kinder to the environment because they limit harmful gas emissions when exposed to high temperatures. So, it’s not just about performance; it’s about ensuring our planet and the devices we use are safe and sound.

- What constitutes a Halogen-free PCB?

- At its core, a Halogen-free PCB is primarily made up of a halogen-free copper-clad laminate. But it’s not just about what it contains; it’s equally about what it excludes – those pesky harmful halogens.

- How can I identify if a PCB is Halogen-free?

- Ah, the age-old question! Well, the Material Data Sheets (MDS) provided by manufacturers are a good starting point. But if you’re ever in doubt, reach out to the supplier or manufacturer. And if you’re feeling a bit adventurous, there are some simple tests like the Odor Test or Flame Test, but always prioritize safety.

- Are there specific applications where Halogen-free PCBs are more beneficial?

- Absolutely! Think of places or devices where environmental concerns are top of mind, or where there’s exposure to high temperatures. In such scenarios, Halogen-free PCBs shine by reducing toxic gas emissions. It’s like having a superhero in the world of PCBs!