Printed circuit boards (PCBs) are the backbone of modern electronics, powering everything from smartphones to cars. But like any electronic component, PCBs can fail over time due to various factors, such as environmental factors, wear and tear, or improper handling. That’s why regular PCB maintenance and repair are essential to keep your devices running smoothly and prevent costly downtime. In this blog post, we’ll discuss the importance of PCB maintenance and repair and provide tips and best practices to help you keep your PCBs in top condition.

Regular Inspection

- The first step in PCB maintenance is to conduct regular inspections to detect any signs of wear, damage, or corrosion. This can include checking for loose or damaged components, broken traces, and signs of moisture or oxidation. You can use a magnifying glass or microscope to inspect the board thoroughly, looking for any abnormalities that could affect its performance.

Cleaning

- Cleaning is an essential part of PCB maintenance, as it helps remove dirt, dust, and other contaminants that can affect the board’s performance. You can use a soft brush or compressed air to remove debris from the board’s surface, being careful not to damage any components or traces. You can also use isopropyl alcohol to clean the board, but be sure to avoid using harsh chemicals or solvents that could damage the board or components.

Component Replacement

- If you find any damaged or faulty components during your inspection, it’s essential to replace them promptly to prevent further damage to the board. This can include replacing broken or loose connectors, damaged capacitors, or burnt-out resistors. When replacing components, be sure to use high-quality components that meet or exceed the board’s specifications to ensure optimal performance.

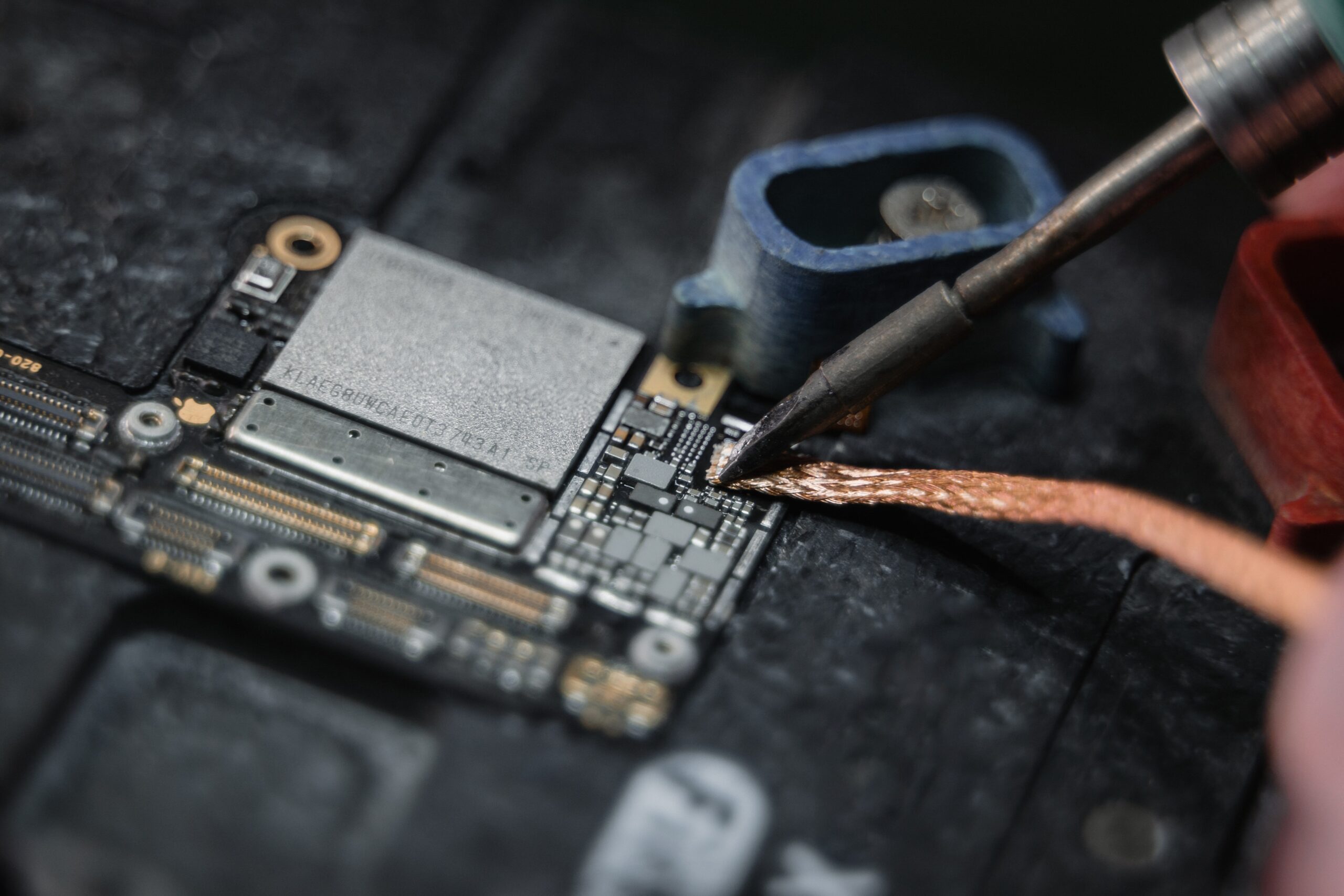

Repairing Traces

- Traces are the conductive paths that connect components on the PCB, and they can become damaged or broken over time due to various factors. If you detect any broken or damaged traces during your inspection, you can repair them using a conductive ink or wire. To repair a trace using conductive ink, you can apply a small amount of ink to the broken section of the trace and let it dry. Alternatively, you can use a wire to bridge the gap between the two ends of the trace, soldering the wire in place to ensure a secure connection.

Preventative Measures

- Prevention is always better than cure, and there are several preventative measures you can take to ensure the longevity of your PCBs. This includes using protective coatings to prevent moisture or corrosion, storing PCBs in a dry and cool environment, and avoiding exposure to extreme temperatures or humidity.

In conclusion, regular PCB maintenance and repair are essential to keep your devices running smoothly and prevent costly downtime. By conducting regular inspections, cleaning the board, replacing faulty components, repairing traces, and taking preventative measures, you can ensure the longevity and optimal performance of your PCBs. If you need professional PCB maintenance or repair services, don’t hesitate to contact us at Rowsum for assistance.