Introduction to Mouse Bites and V-Groove PCB

What are Mouse Bites?

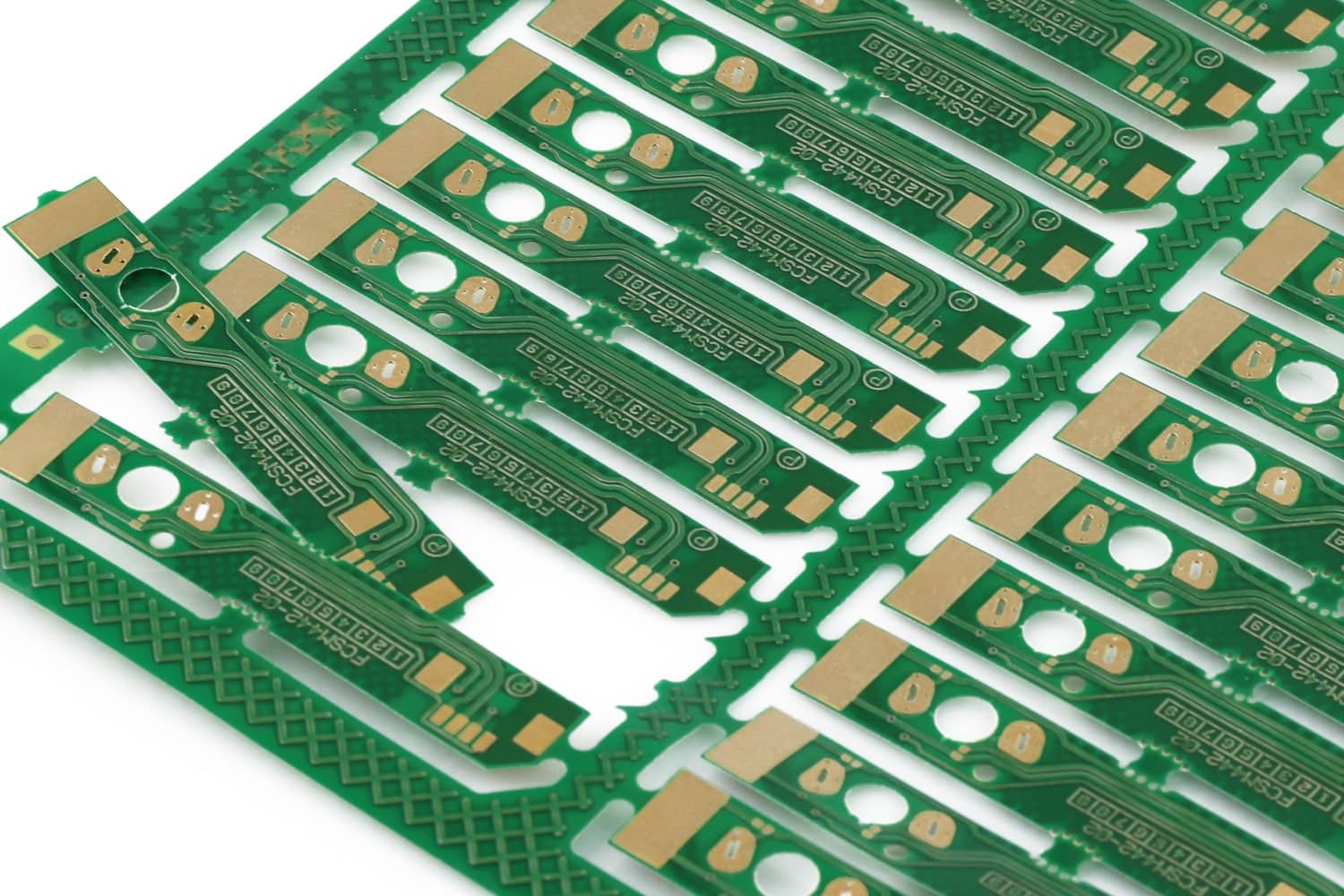

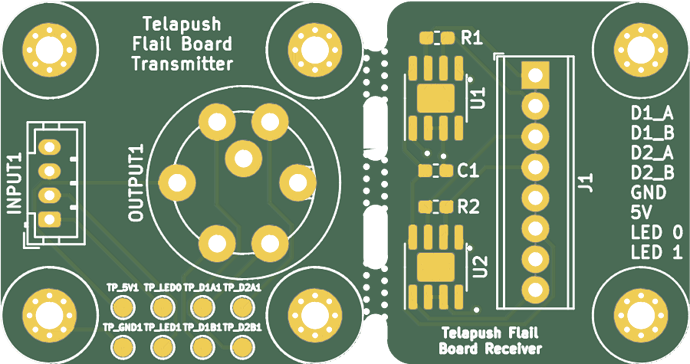

Mouse bites are small holes or perforations in a printed circuit board (PCB) used to separate individual boards from a larger panel. These holes are typically arranged in a row along the board edges, making it easier for the user to break the board apart. Mouse bites are a popular method for creating breakaway tabs, which enable cost-effective manufacturing and easy handling of multiple PCBs.

What is V-Groove PCB?

V-Groove PCB is another method of separating individual boards from a panel. It involves cutting a V-shaped groove along the board edges, leaving a thin layer of material that holds the boards together. Once the panel is complete, the user can easily snap the boards apart. V-Groove is a popular choice for PCB manufacturers because it offers clean and precise separation while maintaining the structural integrity of the boards.

Comparison of Mouse Bites and V-Groove PCB

Advantages and Disadvantages

Mouse Bites

Advantages:

- Cost-effective

- Suitable for smaller boards

- Minimal stress on components during separation

Disadvantages:

- Less precise than V-Groove

- Can leave rough edges

- Requires manual force for separation

V-Groove PCB

Advantages:

- Clean and precise separation

- Suitable for larger boards

- Reduces stress on components during separation

Disadvantages:

- Higher manufacturing cost

- Not suitable for boards with components close to the edges

- Requires specialized cutting equipment

Applications

Mouse Bites

Mouse bites are ideal for smaller PCBs with limited space for components. They are commonly used in consumer electronics, IoT devices, and other applications where size and cost are crucial factors.

V-Groove PCB

V-Groove PCB is better suited for larger boards and applications where precise separation and a cleaner finish are important. They are commonly used in automotive, aerospace, and industrial applications, where the boards must withstand harsh environments and maintain high performance.

How to Design and Implement Mouse Bites and V-Groove PCB

Design Guidelines

Mouse Bites

- Space mouse bites evenly along the board edges

- Ensure sufficient clearance between mouse bites and components

- Choose the appropriate hole size for the specific application and manufacturing capabilities

V-Groove PCB

- Ensure adequate clearance between the V-Groove and components

- Consider the board thickness and material when selecting the depth and angle of the V-Groove cut

- Avoid using V-Groove on boards with components very close to the edges

Manufacturing Process

Mouse Bites

- Drill small holes or perforations along the edges of the PCB panel

- Space the holes evenly and maintain a consistent size for easy separation

- Inspect the panel for any defects or irregularities in the mouse bites

V-Groove PCB

- Use specialized cutting equipment to create V-shaped grooves along the PCB panel edges

- Adjust the depth and angle of the cut based on the board material and thickness

- Inspect the panel for consistent groove depth and clean edges

Tips for Selecting the Right PCB Breakaway Method

- Consider the size and complexity of your PCBs. Mouse bites are more suitable for smaller boards, while V-Groove is ideal for larger ones.

- Evaluate the manufacturing costs. Mouse bites are generally more cost-effective, while V-Groove may have a higher manufacturing cost.

- Analyze the required level of precision and finish. V-Groove provides cleaner and more precise separation than mouse bites.

- Assess the stress on components during separation. Both methods have their advantages and disadvantages, but V-Groove typically reduces stress on components.

- Consult with your PCB manufacturer to determine the best breakaway method for your specific needs and requirements.

Conclusion

Choosing the right PCB breakaway method is crucial for achieving high-quality results and ensuring the functionality and reliability of your boards. By understanding the differences between mouse bites and V-Groove PCB, as well as considering factors such as board size, cost, precision, and stress on components, you can make an informed decision that best suits your specific application.

FAQs

- Can I use both mouse bites and V-Groove on the same PCB?

Yes, it is possible to use both methods on the same PCB, depending on your design and manufacturing requirements.

- Which breakaway method is faster for separating boards?

V-Groove is generally faster because it requires less manual force for separation compared to mouse bites.

- Are there other PCB breakaway methods besides mouse bites and V-Groove?

Yes, other methods include scored lines and routed slots, each with their own advantages and disadvantages.

- How do I choose the right hole size for mouse bites?

The hole size depends on your specific application and manufacturing capabilities. Consult with your PCB manufacturer for guidance.

- Do mouse bites and V-Groove affect the overall performance of a PCB?

Both methods can be used without significantly impacting the performance of the PCB, provided they are designed and implemented correctly.